Plastics in Building Materials & Products

How much plastic is used in buildings?

Building materials are a significant and growing sector of plastic use. Globally, building and construction is the second-highest-use sector for plastics, accounting for 17% of total plastic production. It’s surpassed only by packaging, which accounts for roughly 31%.

Without intervention, the demand for plastic building materials is projected to triple by 2060 from 2019 levels.

Where are plastics found in buildings?

Products made either wholly or partially from plastic can be found throughout commercial and residential buildings. Below are examples of where plastics are used in buildings and what specific materials are used to make them.

Plumbing: PEX (medium- or high-density polyethylene), PVC (polyvinyl chloride), and CPVC (chlorinated polyvinyl chloride)

Siding: House wrap membrane (polyethylene) and PVC (vinyl siding and trim)

Paint: Acrylic paints and polyurethanes

Insulation: Expanded polystyrene foam insulation (EPS) and extruded polystyrene foam insulation (XPS)

Flooring: Vinyl sheet flooring, luxury vinyl plank or tiling (PVC), and carpet (nylon, polypropylene, polyester, etc.)

Countertops: Plastic laminates

Windows and doors: PVC

Decking: Composite and PVC decking

What are the problems with using plastics in building materials?

While plastic building products have benefits — such as ease of installation, ease of maintenance, and lower initial cost — they also threaten environmental and human health across the entirety of their life cycles.

Toxic pollution and chemical exposure

The majority of plastics are made from fossil fuels and chemicals, and the extraction and refining of the raw materials used to manufacture these products have well-documented climate and health impacts that disproportionately affect Indigenous communities and communities of color in the United States.

Plastic lumber used for decking and benches can reach hot temperatures, posing a burn risk, these materials may also release toxic chemicals when burned, and often flake, releasing small pieces of plastic where they are installed. In addition, when sawed or milled by contractors, plastic lumber releases very fine plastic particles that look like snow that may pollute soil and water, as well as flow into storm drains where they can travel farther.

Polyvinyl chloride (PVC) plastic piping used for drinking water raises concerns about potential human health impacts due to data showing that the leaching of toxic chemicals may occur. Communities that opt to replace their lead service lines with PVC plastic pipes may well be leaping from the frying pan into the fire. Although it is imperative to replace lead service lines, it is critical to choose a non-toxic replacement pipe material. Find more information on this in the 2023 Beyond Plastics report, The Perils of PVC Plastic Pipes.

When buildings are burned in structure fires or wildfires, any plastic materials within them release hazardous chemicals. These chemicals may harm firefighters and other first responders and contaminate nearby soil, water, and biological habitats. The tragic fires in Los Angeles, CA in January 2025 are an illustration of the need to embrace safer building materials and products.

Climate change impacts

As of 2024, the plastics industry releases nearly four times as many climate-warming emissions as the global air travel industry.

The manufacture of PVC and other plastics largely use fossil fuels as feedstock, including natural gas and coal.

In 2023, plastic production was responsible for 4.5% of global greenhouse gas emissions. Without a reduction in plastics production, their emissions footprint is forecasted to triple by 2100.

Waste management and disposal

The majority of plastic building material waste is landfilled or incinerated. Recycling or reuse of plastic products in the building sector is rare.

For example, discarded carpeting accounts for about 1.1 million tons of plastic waste each year in the United States — roughly equivalent to all of the plastic bag, straw, and single-use water bottle waste generated annually.

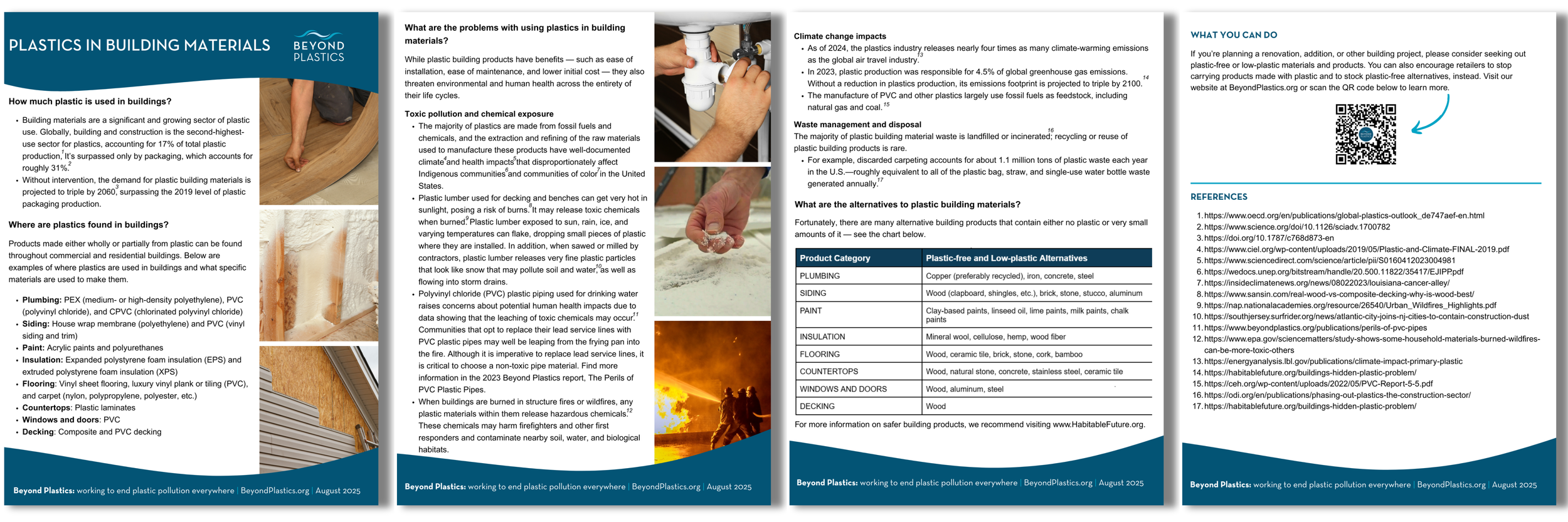

What are the alternatives to plastic building products?

Fortunately, alternative building products exist that contain either no plastic or very small amounts of it — see the chart below.

For more information on safer building products, we recommend visiting Habitable.

What You Can Do

Choose non-plastic building materials. If you’re planning an addition, renovation, deck, or other building project, take the time to find and use building materials and products that do not contain plastic.

Spread the word. Share this fact sheet with your friends and family to help them make more informed decisions.

Urge Home Depot to stop selling products made with polyvinyl chloride plastic (PVC) aka “the poison plastic”. Click here to add your name to our petition now.

More Resources

The Los Angeles wildfires are finally contained, but Californians still aren’t safe (op-ed by Judith Enck and Heather McTeer Toney) | The Hill | February 2025

Vinyl Chloride: The Poison That Makes the Plastic | Beyond Plastics | July 2024

Buildings’ Hidden Plastic Problem | Habitable | November 2024

The Perils of PVC Plastic Pipes | Beyond Plastics | April 2023